02 Feb,2026

02 Feb,2026

Is Your Dust Collector System Truly Efficient and Compl...

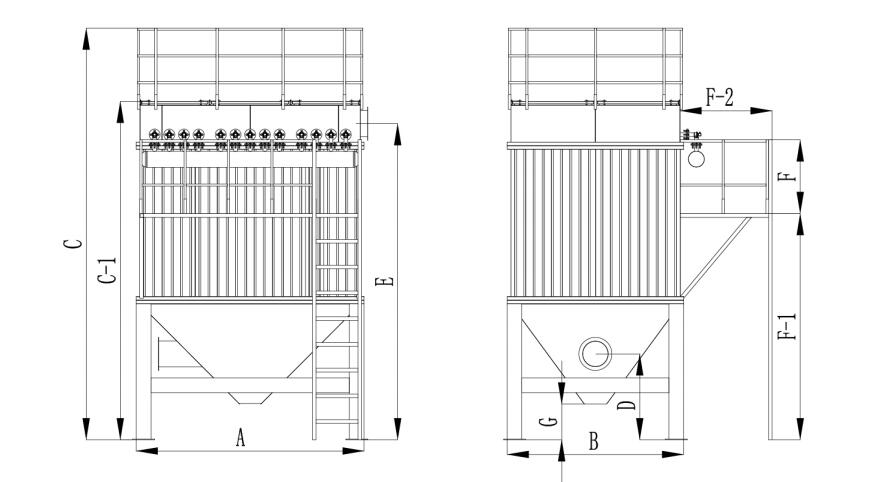

Baghouse dust collectors are dry-type dust removal devices suitable for capturing fine, dry, non-fibrous dust. Filter bags are made from woven filter cloth or non-woven felt, utilizing the filtration properties of fibrous fabrics to filter dust-laden gas. When dust-laden gas enters the baghouse, larger particles with higher specific gravity settle under gravity and fall into the hopper. Ash hopper. As the gas containing finer dust passes through the filter material, the dust particles are retained, purifying the gas. The baghouse dust collector primarily consists of an upper housing, middle housing, lower housing (ash hopper), pulse cleaning system, and ash discharge mechanism. It is widely used in flue gas treatment and dust collection systems for steel mills, foundries, power plants, and similar facilities. Applications also include asphalt concrete mixing, building materials, water and ceramics, lime, gypsum, and other production sites. It is also used for flue gas filtration in aluminum electrolysis, lead, tin, zinc, copper, and other rare metal smelting, as well as fine material recovery. Additionally, it serves liquid-solid separation and fine material recovery in chemical, coke, carbon black, dye, pharmaceutical, and plastic industries. Furthermore, it addresses dust control and purification collection in mining, grain processing, flour milling, electronics, and woodworking sectors.

Installation Dimensions and Selection Criteria for Pulse Jet Baghouse Dust Collectors

| Model | Air Volume (m³/h) | Equipment Overall Dimension | Number of Bags | Bag Specification | Pulse Configuration Inch/Piece/Bag |

Fan Power (kw) |

| DMC-16 | 1000 | 760×760×3800 | 16 | ∅133*2000 | 4 per 1 inch | 2.2kw |

| DMC-24 | 2000 | 1060×750×4000 | 24 | ∅133*2000 | 6per 1 inch | 2.2kw |

| DMC-36 | 3000 | 1070×1070×4100 | 36 | ∅133*2000 | 6per 1 inch | 3kw |

| DMC-48 | 4000 | 1440×1070×4200 | 48 | ∅133*2000 | 8per 1 inch | 4kw |

| DMC-64 | 5000 | 1440×1440×4300 | 64 | ∅133*2000 | 8per 1 inch | 5.5kw |

| DMC-72 | 6000 | 1550×1440×4400 | 72 | ∅133*2000 | 9per 1 inch | 5.5kw |

| DMC-80 | 6000 | 1770×1440×4400 | 80 | ∅133*2000 | 10per 1 inch | 7.5kw |

| DMC-96 | 7000 | 2100×1440×4400 | 96 | ∅133*2000 | 12per 1 inch | 11kw |

| DMC-100 | 8000 | 1770×1770×4400 | 100 | ∅133*2000 | 10per 1 inch | 11kw |

| DMC-120 | 10000 | 2100×1770×4400 | 120 | ∅133*2000 | 12per 1 inch | 15kw |

| DMC-160 | 14000 | 2780×1770×4400 | 160 | ∅133*2000 | 16per 1 inch | 18.5kw |

| DMC-200 | 16000 | 3400×1770×4600 | 200 | ∅133*2000 | 20per 1 inch | 22kw |

Note: Due to site constraints or transportation limitations, the number of ash hoppers in pulse jet baghouse dust collectors may vary, ranging from one to multiple units.

Discharge ports can be equipped with optional pneumatic valves, electric valves, or automatic unloaders.

Design Calculations for Pulse Jet Baghouse Dust Collectors

The design and selection of pulse jet baghouse dust collectors require the following technical parameters:

1. Characteristics of the dust-laden gas to be treated; determine the dust type

2. Determine the cleaning method

3. Filter media (material of the filter bags)

4. Filtration velocity

5. Airflow volume

|

Service unit customers

National Engineering Cases

Hangzhou Lvran Environmental Protection Group Co., Ltd. is a comprehensive waste gas treatment system engineering service provider and equipment manufacturer, integrating R&D, technical services, design, production, engineering installation, and after-sales service.

We are China Baghouse dust collector Suppliers and Wholesale Baghouse dust collector Exporter, Company. The Group is a national high-tech enterprise, a Zhejiang Province science and technology enterprise, a regional R&D center, and an AAA-rated credit unit. It holds over 30 utility model patents, numerous invention patents, and software copyrights. The Group has long-standing technical R&D collaborations with domestic universities and institutions, including the "Environmental Innovation R&D Center" established with Anhui University of Science and Technology and the "Plasma Energy and Environmental New Technology R&D Center" jointly developed with Zhejiang Sci-Tech University. The Group has established its own R&D and production base for in-depth technical collaboration. The Group possesses core VOC gas treatment technology, holds a Level 2 general contracting qualification for municipal public works construction, a safety production license, a Class B special design qualification for environmental pollution control in Zhejiang Province, unclassified labor service qualifications, and specialized contracting for special projects. The Group is certified to ISO9001 for international quality, ISO14001 for environmental management, and ISO45001 for occupational health and safety.

02 Feb,2026

02 Feb,2026

22 Jan,2026

22 Jan,2026

15 Jan,2026

15 Jan,2026

08 Jan,2026

08 Jan,2026

01 Jan,2026

01 Jan,2026