02 Feb,2026

02 Feb,2026

Is Your Dust Collector System Truly Efficient and Compl...

Introduction to the Process Principle and Features of Odor Removal Equipment

The biological filter deodorization process employs a biological method to eliminate odorous gases. Compared to traditional physicochemical treatment methods, the biological approach offers advantages such as avoiding or reducing secondary pollution, lower investment costs, reduced energy consumption, minimal operating expenses, simple equipment, and high deodorization efficiency—achieving over 90% effectiveness.

The process principle of biological filter deodorization relies on microbial biodegradation to absorb and degrade malodorous substances, thereby achieving odor removal.

Odorous gases pass through a moist, porous filter bed densely populated with active microorganisms. Utilizing the adsorption, absorption, and degradation capabilities of microbial cells, these microorganisms—characterized by small cell size, large surface area, strong adsorption capacity, and diverse metabolic pathways—adsorb malodorous substances and decompose them into simple inorganic compounds such as CO, H₂O, H₂SO₄, and HNO₃.

The biological filter method achieves high deodorization efficiency and is suitable for treating large volumes of low-concentration exhaust gases.

|

Deodorization Mechanism

Based on the absorption-biofilm theory, microbial deodorization proceeds through the following steps:

(1) Pollutants in the exhaust gas first come into contact with water and dissolve into it (i.e., diffuse from the gas phase into the liquid phase);

(2) Pollutants dissolved in the liquid phase further diffuse into the biofilm driven by concentration gradients, where they are captured and adsorbed by microorganisms;

(3) Microorganisms convert pollutants into biomass, metabolic byproducts, and other harmless substances (e.g., CO₂, H₂O, N₂, S, and SO₄²⁻);

(4) Reaction products like CO₂ and N₂ desorb from the biofilm surface and rediffuse into the gas phase, while other substances (e.g., S and SO₄²⁻) are discharged with the nutrient solution or retained within the microorganisms.

Product Description: Explanation of Biological Deodorization Process Principles and Performance Characteristics

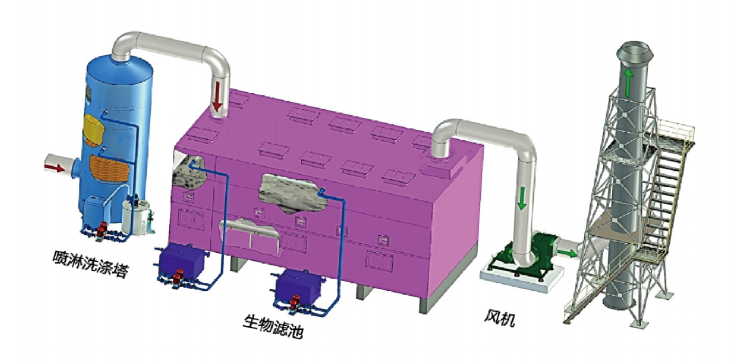

The combined biological scrubbing and filtration deodorization unit integrates three biological technologies: biological scrubbing, biological trickling filtration, and biological filtration. This novel composite biological deodorization device was developed by synthesizing the advantages of these three biological techniques. Odorous gases enter the scrubbing zone via the inlet, where they undergo preliminary treatment with water or concentrated chemical scrubbing solutions. This scrubbing zone completes the absorption of water-soluble chemicals, dust removal, and humidification of the odorous gases. Unremoved malodorous gases then proceed to the multi-stage biofilter bed filtration zone. As they pass through the filter layer, pollutants transfer from the gas phase to the surface of the biofilm:

a) Under sprayed water action, malodorous gases contact and dissolve within the water film on the moist packing material (biological media).

b) Malodorous components entering the biofilm are degraded within the packing material through microbial absorption and decomposition.

c) Microorganisms utilize absorbed malodorous components as an energy source for further reproduction. These three processes occur simultaneously, ensuring the entire system

meets emission standards.

Determination of Process Parameters

1. Selection of Water Pumps

2. Packing Height: Approximately 0.8–1.2 m

3. Gas Velocity

Gas residence time within the equipment: 5–25 seconds (Our equipment typically achieves over 20 seconds of empty tower residence time)

Gas velocity controlled at 0.2–0.5 m/s. (Tower gas velocity is the linear velocity of mixed gas calculated based on the empty tower cross-sectional area; maximum gas volume occurs at the tower base, typically used for calculation.)

Our equipment employs spherical polymeric organic packing, D=50 mm, (voidage) = 0.73

The effective volume and height of the biofilter and biofill material shall be calculated using the following formula:

V = QT / 3600

H = VT / 3600

Where:

V = Effective volume of the packing layer (m³)

Q = Odorous gas flow rate (m³/h)

T = Empty tower residence time (s)

H = Height of the packing layer (m)

V = Empty tower gas velocity (m/s)

Performance Advantages of Biological Odor Control

● High Treatment Efficiency and Superior Odor Removal

Microbial filtration odor control equipment effectively eliminates specific pollutants such as hydrogen sulfide, ammonia, and methyl mercaptan, delivering outstanding odor removal with an efficiency exceeding 95%.

It meets the most stringent odor control environmental requirements across diverse regions under any seasonal or climate conditions.

Advanced and Rational Deodorization Process

The advanced and rational deodorization process ensures final emissions are harmless to humans and animals. This environmentally friendly technology causes no secondary pollution.

● Microbial Activity

Only a small amount of nutrient agent is required during the initial operation. Microorganisms maintain optimal activity by absorbing nutrients from exhaust gases.

● High Shock Load Tolerance

The system automatically adjusts to peak exhaust gas concentrations, ensuring continuous microbial operation with strong shock load tolerance. This represents the most distinctive feature and advantage of spray-microbial filtration deodorization equipment compared to other methods.

● Extended biological media lifespan

Specially processed biological media exhibit high specific surface area, facilitate biofilm formation and detachment, resist corrosion and biodegradation, provide excellent thermal insulation, feature high porosity, minimal pressure drop, and efficient gas/water distribution. Service life reaches 8–10 years.

● Simple Operation, Maintenance-Free

Requires no dedicated personnel or routine maintenance. Extremely low operational costs with convenient management. Capable of continuous 24-hour operation or intermittent use.

Minimal-wear components ensure exceptionally straightforward maintenance.

● Automatic Control, Fully Automated Operation

Features fully automated control with both remote and local operation options, plus manual and automatic control modes. Process operations run fully automatically per preset parameters, ensuring highly stable performance. This enables virtually unattended management with no manual intervention required—workers need only conduct routine inspections.

● Integrated or Modular Assembly

Facilitates transportation and installation. Expanding odor treatment capacity simply requires adding components, making implementation straightforward and enabling separate processing under gas source conditions.

● Low Pressure Drop, Energy Efficiency

The packing material possesses excellent structural stability and air permeability, ensuring a long service life. Consequently, the equipment exhibits low pressure drop and low operational energy consumption.

● Minimal Operating Costs

Operational electricity costs are minimal. For standard equipment, annual electricity expenses range between 6,000 and 18,000 yuan, depending on size.

With ongoing refinement of biological deodorization technology and leveraging this equipment's unique advantages, its application prospects are expanding rapidly in municipal wastewater treatment plants and organic volatile compound (VOC) treatment within the chemical and pharmaceutical industries.

During initial operation, only a small amount of the nutrient agent is required. Microorganisms maintain optimal activity by continuously absorbing nutrients from the exhaust gas.

Service Advantages

1. Utilizes biotechnology for eco-friendly and hygienic operation with zero secondary pollution.

2. Capable of simultaneously treating exhaust gases containing multiple pollutants.

3. High shock resistance ensures stable operation even when exhaust gas concentrations fluctuate between 3-1500ppm.

4. Short processing time and high efficiency. Purification completes in 5-10 seconds with overall efficiency exceeding 95%.

5. Single-step biofilm establishment using diverse microbial strains with minimal inoculation time.

6. Low construction and operational costs; no chemical additives required.

7. Constructed from fiberglass/stainless steel for aesthetic appeal, superior corrosion resistance, and extended service life.

8. Utilizes composite filter media with large surface area, excellent air permeability, resistance to clogging, and extended service life.

9. PLC-controlled system ensures high automation.

10. Double-layer structure with insulation material in the interlayer for cold-weather operation; inner layer features anti-corrosion coating.

Service unit customers

National Engineering Cases

Hangzhou Lvran Environmental Protection Group Co., Ltd. is a comprehensive waste gas treatment system engineering service provider and equipment manufacturer, integrating R&D, technical services, design, production, engineering installation, and after-sales service.

We are China FRP biological deodorization filter Suppliers and Wholesale FRP biological deodorization filter Exporter, Company. The Group is a national high-tech enterprise, a Zhejiang Province science and technology enterprise, a regional R&D center, and an AAA-rated credit unit. It holds over 30 utility model patents, numerous invention patents, and software copyrights. The Group has long-standing technical R&D collaborations with domestic universities and institutions, including the "Environmental Innovation R&D Center" established with Anhui University of Science and Technology and the "Plasma Energy and Environmental New Technology R&D Center" jointly developed with Zhejiang Sci-Tech University. The Group has established its own R&D and production base for in-depth technical collaboration. The Group possesses core VOC gas treatment technology, holds a Level 2 general contracting qualification for municipal public works construction, a safety production license, a Class B special design qualification for environmental pollution control in Zhejiang Province, unclassified labor service qualifications, and specialized contracting for special projects. The Group is certified to ISO9001 for international quality, ISO14001 for environmental management, and ISO45001 for occupational health and safety.

02 Feb,2026

02 Feb,2026

22 Jan,2026

22 Jan,2026

15 Jan,2026

15 Jan,2026

08 Jan,2026

08 Jan,2026

01 Jan,2026

01 Jan,2026