02 Feb,2026

02 Feb,2026

Is Your Dust Collector System Truly Efficient and Compl...

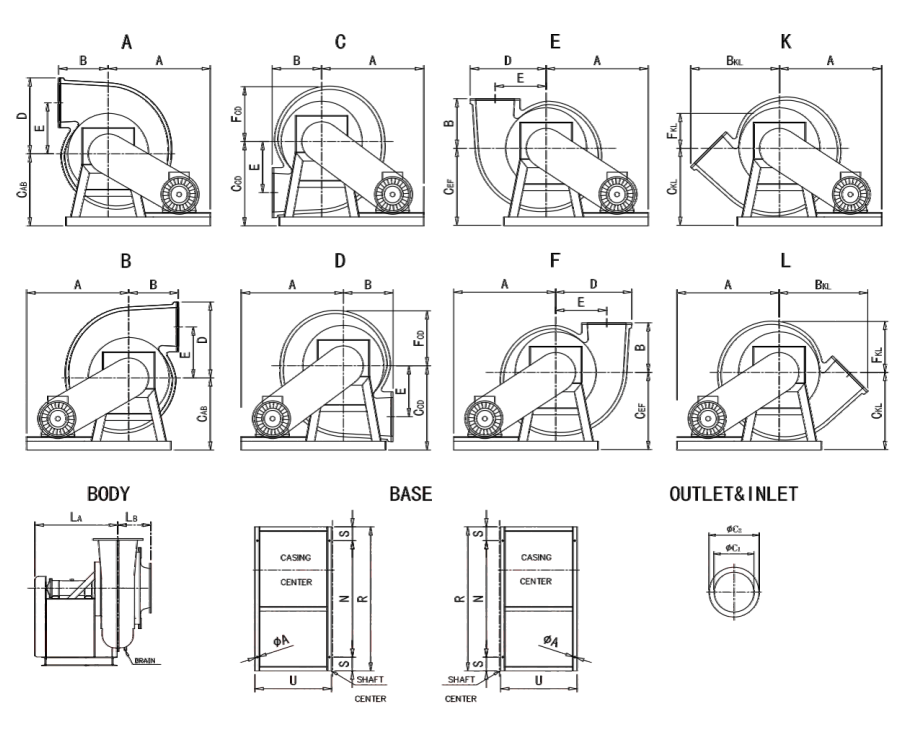

GF Series

FRP High-Pressure Corrosion-Resistant Fan

Performance Range:

Airflow Range: 200-100,000 CMH

Maximum Static Pressure: 10000 Pa

GreenYi static fans incorporate cutting-edge design concepts, engineered using PROE and CAD systems, and meticulously crafted from premium international resins and fiberglass. They deliver stable operation, exceptional performance, and an aesthetically pleasing appearance.

Impeller and casing molds utilize 3D carving instead of traditional manual molding, achieving single-piece precision with fine details.

Finite element simulation analyzes structural integrity, revolutionizing impeller bonding techniques to enhance manufacturing precision and structural strength, thereby improving ventilation efficiency.

Each fan inlet undergoes individual flanging, with reinforced shaft sealing to eliminate pre-embedded bolt and shaft seal leakage at the source.

Spectral analysis, dynamic balancing machine inspection, standardized tooling assembly, and comprehensive quality testing ensure precise performance and long-term stable operation.

Applied in harsh environments involving the transport of corrosive exhaust gases containing strong acids and alkalis, such as acid and alkali exhaust ventilation and recovery systems across numerous industries, including petroleum, chemical, pharmaceutical, pesticide, electronics, photovoltaic, papermaking, new energy, sewage deodorization, hazardous and solid waste, and landfill leachate.

For special conditions or gases, customized protective solutions are available based on actual requirements:

FRP corrosion-resistant explosion-proof fans, FRP corrosion-resistant flame-retardant fans, FRP corrosion-resistant high-temperature fans (<80℃), FRP acid/alkali-resistant and organic solvent-resistant fans (excluding special solvents), FRP chromic acid-resistant fans, FRP hydrofluoric acid-resistant fans, FRP low-noise soundproof enclosure fans, etc.

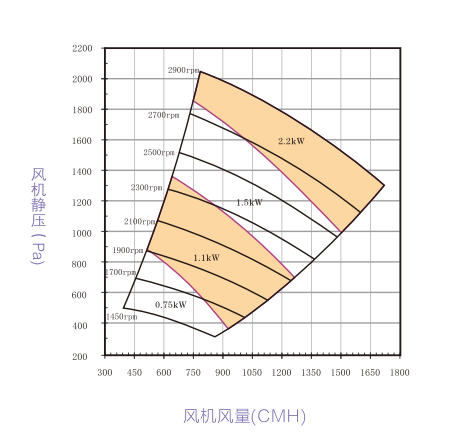

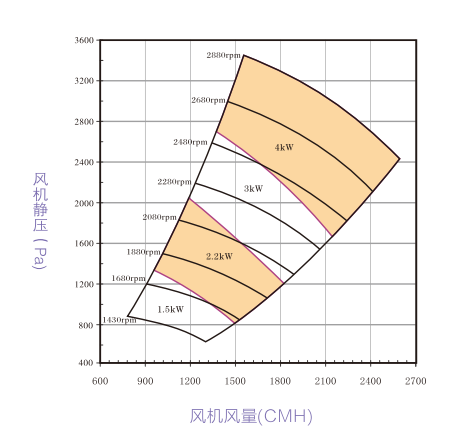

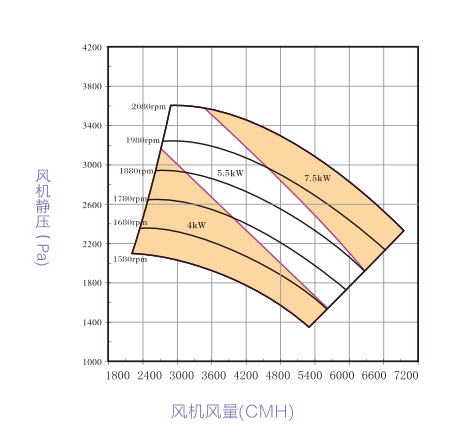

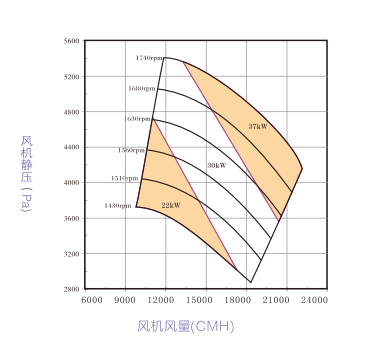

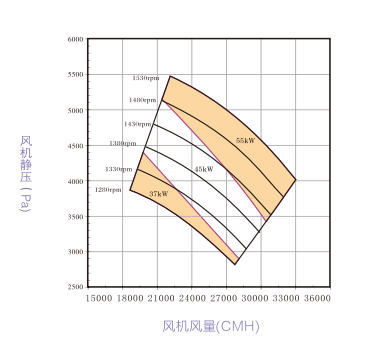

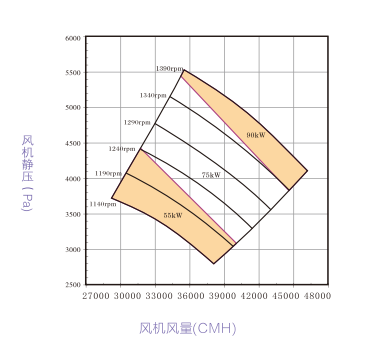

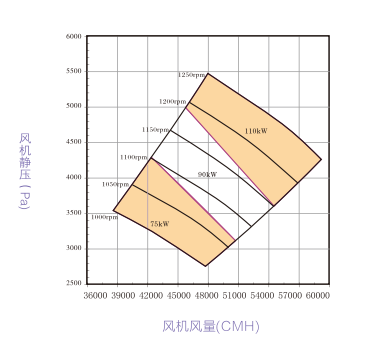

Summary table of performance curve

|

| GF-400P | GF-500P |

|

|

| GF-600P | GF-800P |

|

|

|

| GF-1000P | GF-1100P |

|

|

| GF-1300P | GF-1500P |

|

|

| GF-1600P | GF-1800P |

|

|

|

Service unit customers

National Engineering Cases

Hangzhou Lvran Environmental Protection Group Co., Ltd. is a comprehensive waste gas treatment system engineering service provider and equipment manufacturer, integrating R&D, technical services, design, production, engineering installation, and after-sales service.

We are China FRP high pressure blower Suppliers and Wholesale FRP high pressure blower Exporter, Company. The Group is a national high-tech enterprise, a Zhejiang Province science and technology enterprise, a regional R&D center, and an AAA-rated credit unit. It holds over 30 utility model patents, numerous invention patents, and software copyrights. The Group has long-standing technical R&D collaborations with domestic universities and institutions, including the "Environmental Innovation R&D Center" established with Anhui University of Science and Technology and the "Plasma Energy and Environmental New Technology R&D Center" jointly developed with Zhejiang Sci-Tech University. The Group has established its own R&D and production base for in-depth technical collaboration. The Group possesses core VOC gas treatment technology, holds a Level 2 general contracting qualification for municipal public works construction, a safety production license, a Class B special design qualification for environmental pollution control in Zhejiang Province, unclassified labor service qualifications, and specialized contracting for special projects. The Group is certified to ISO9001 for international quality, ISO14001 for environmental management, and ISO45001 for occupational health and safety.

02 Feb,2026

02 Feb,2026

22 Jan,2026

22 Jan,2026

15 Jan,2026

15 Jan,2026

08 Jan,2026

08 Jan,2026

01 Jan,2026

01 Jan,2026