02 Feb,2026

02 Feb,2026

Is Your Dust Collector System Truly Efficient and Compl...

Bag filter is a dry dust removal device, which is suitable for capturing fine, dry non-fibrous dust. The filter bag is made of textile filter cloth or non-textile, and uses the filtering effect of fiber fabric to filter dust-containing gas. When the dust-containing gas enters the bag filter, the large particles and heavy dust settle down due to gravity and fall into the ash hopper; when the gas containing finer dust passes through the filter material, the dust is retained, so that the gas is purified.

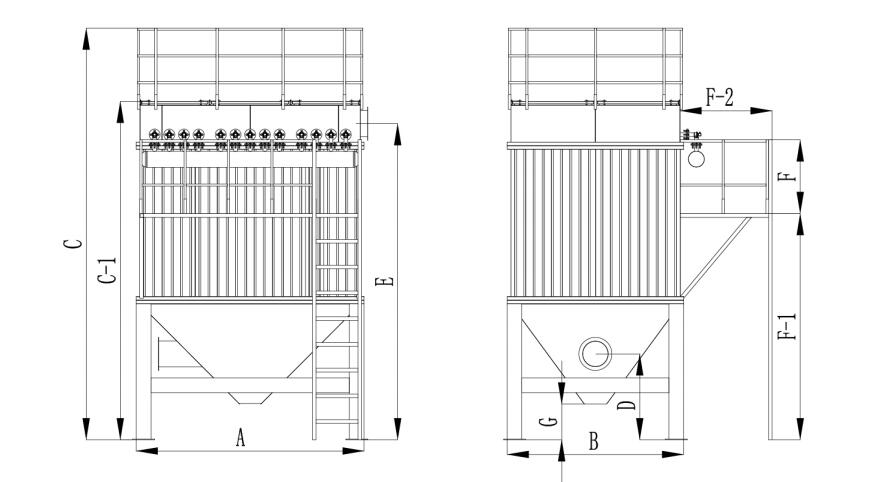

The bag filter structure is mainly composed of the upper box, middle box, lower box (ash hopper), pulse cleaning system and ash discharge mechanism. It is widely used in flue gas treatment and dust removal systems in steelmaking, foundries, power plants, etc.; asphalt concrete mixing; production sites of building materials, cement ceramics, lime, gypsum, etc.; smelting flue gas filtration and fine material recovery in aluminum electrolysis, lead, tin, zinc, copper and other rare metals; liquid-solid separation and fine material recovery in the fields of chemical, coke, carbon black, dyes, pharmaceuticals, plastics, etc.; dust treatment and purification collection in mining, grain processing, flour, electronics industry, wood processing, etc.

advantage:

● High dust removal efficiency, capable of capturing dust larger than 0.3nm and purifying dust-laden gas to 15mg/m³ or even below.

● There are fewer ancillary equipment, less investment, and the technical requirements are not as high as those of electrostatic precipitators.

● It can capture dust that is difficult to recover by electrostatic precipitator; and to a certain extent, it can collect compounds such as nitrates and sulfides.

● Good adaptability to load changes, especially suitable for capturing fine and dry dust, the collected dry dust is easy to handle and recycle;

● Bag dust collectors are safer when collecting dust-laden gases that are explosive or contain sparks.

Dust removal device type:

According to the mechanism of dust collection, it can be divided into four types: mechanical dust collector, washing dust collector, filtering dust collector (bag dust collector) and electrostatic dust collector.

The working principle of the pulse bag filter is to use the filter bag made of fiber woven material to filter dust and purify the dust flow. If a certain degree of dust accumulates on the filter bag, the filter bag is cleaned and washed by compressed air in the form of pulses, so as to achieve the purpose of cleaning the filter bag. The pulse bag filter will enter the vacuum chamber in the box from the bottom of the box under the action of the suction fan. The dust particles can be trapped on the outer wall of the filter bag. After passing through the filter bag, the air is purified through the exhaust port. Analysis of the working principle of the pulse bag filter: As the dust particles increase, the resistance of the pulse bag filter on the surface of the pulse bag filter increases, which will gradually weaken the filtering capacity. When the resistance of the pulse bag filter reaches a certain time, it needs to be cleared.

At this time, the pulse control instrument of the pulse bag dust collector sends out a signal at a fixed time, opens the electromagnetic pulse valve in sequence, and can quickly pass the compressed air bag through the pulse valve through the hole on the spray gun, and spray a high flow of the ejector. Filter bag, so that the filter bag can expand rapidly, and after blowing, the filter bag will shrink sharply. Analyze the working principle of the pulse bag dust collector: Such expansion and contraction can ensure that the filter bag is in good working condition. Since the dust cleaning process is carried out in sequence and the dust air is not cut off, the dust removal capacity remains basically unchanged during the working process of the pulse bag dust collector.

Dust collector skeleton analysis pulse bag dust collector working principle: in order to meet the requirements of different working conditions, the pulse controller can adjust the pulse interval and pulse width of the pulse bag dust collector at will. If the dust bag is found that the equipment resistance exceeds the limit range and the outlet, if there is obvious dust, it can be checked and adjusted according to these methods. We can use the troubleshooting method: release it to see if it is because of too much dust in the filter bag or because of electromagnetic. When the valve fails, the solenoid valve and control system can be checked, and the dredging pipe can be cleaned. The covering form should be reasonably selected according to the distribution type of the pollution source, process equipment and production operation conditions, so that both can effectively control the dust without affecting the worker's operation and equipment maintenance.

In order to reduce vibration and rigid connection of the reciprocating equipment body, the holes and gaps in the cover must be reduced to ensure a tight and tight shell. According to the process operation requirements, the necessary working holes, inspection doors and observation holes should be set, the door holes should be tight, easy to install, and the opening and closing components should be flexible. Minimize the open area as much as possible. The opening position should be away from the positive pressure of the shell and avoid the parts with large air flow rate. Generally speaking, the operating temperature requirement of the pulse bag dust collector must be higher than the acid dew point temperature by more than 25K, which is safe for the dust bag to operate. This is mainly to avoid condensation when the operating temperature is lower than the dew point. INT will produce liquid water. The liquid water mixed with dust gathered on the surface of the filter bag can form a paste bag.

Pulse bag dust collector installation size and selection

| Model | Air volume (m³/h) | Equipment dimensions (mm) | Number of bags | Bag specifications | Pulse Configuration | Fan power |

| DMC-16 | 1000 | 760×760×3800 | 16 | Ø133×2000 | 4pcs/1inch | 2.2kw |

| DMC-24 | 2000 | 1060×750×4000 | twenty four | Ø133×2000 | 6pcs/1inch | 2.2kw |

| DMC-36 | 3000 | 1070×1070×4100 | 36 | Ø133×2000 | 6pcs/1inch | 3kw |

| DMC-48 | 4000 | 1440×1070×4200 | 48 | Ø133×2000 | 8pcs/1inch | 4kw |

| DMC-64 | 5000 | 1440×1440×4300 | 64 | Ø133×2000 | 8pcs/1inch | 5.5kw |

| DMC-72 | 6000 | 1550×1440×4400 | 72 | Ø133×2000 | 9 pieces/1 inch | 5.5kw |

| DMC-80 | 6000 | 1770×1440×4400 | 80 | Ø133×2000 | 10pcs/1inch | 7.5kw |

| DMC-96 | 7000 | 2100×1440×4400 | 96 | Ø133×2000 | 12pcs/1inch | 11kw |

| DMC-100 | 8000 | 1770×1770×4400 | 100 | Ø133×2000 | 10pcs/1inch | 11kw |

| DMC-120 | 10000 | 2100×1770×4400 | 120 | Ø133×2000 | 12pcs/1inch | 15kw |

| DMC-160 | 14000 | 2780×1770×4400 | 160 | Ø133×2000 | 16pcs/1inch | 18.5kw |

| DMC-200 | 16000 | 3400×1770×4600 | 200 | Ø133×2000 | 20pcs/1inch | 22kw |

Note: Due to site restrictions or transportation restrictions, the number of hoppers for pulse bag dust collectors may vary: 1 or more, etc. The discharge port can be equipped with pneumatic valves, electric valves, and automatic dischargers.

Design and calculation of a pulse bag dust collector

The design and selection of pulse bag dust collectors require the above technical parameters:

1. Characteristics of the dust-laden gas to be treated; (determine the type of dust)

2. Determine the cleaning method;

3. Filter material (bag material)

4. Filtration wind speed;

5. Air volume;

Service unit customers

National Engineering Cases

Hangzhou Lvran Environmental Protection Group Co., Ltd. is a comprehensive waste gas treatment system engineering service provider and equipment manufacturer, integrating R&D, technical services, design, production, engineering installation, and after-sales service.

We are China Pulse Bag Filter Suppliers and Wholesale Pulse Bag Filter Exporter, Company. The Group is a national high-tech enterprise, a Zhejiang Province science and technology enterprise, a regional R&D center, and an AAA-rated credit unit. It holds over 30 utility model patents, numerous invention patents, and software copyrights. The Group has long-standing technical R&D collaborations with domestic universities and institutions, including the "Environmental Innovation R&D Center" established with Anhui University of Science and Technology and the "Plasma Energy and Environmental New Technology R&D Center" jointly developed with Zhejiang Sci-Tech University. The Group has established its own R&D and production base for in-depth technical collaboration. The Group possesses core VOC gas treatment technology, holds a Level 2 general contracting qualification for municipal public works construction, a safety production license, a Class B special design qualification for environmental pollution control in Zhejiang Province, unclassified labor service qualifications, and specialized contracting for special projects. The Group is certified to ISO9001 for international quality, ISO14001 for environmental management, and ISO45001 for occupational health and safety.

02 Feb,2026

02 Feb,2026

22 Jan,2026

22 Jan,2026

15 Jan,2026

15 Jan,2026

08 Jan,2026

08 Jan,2026

01 Jan,2026

01 Jan,2026