02 Feb,2026

02 Feb,2026

Is Your Dust Collector System Truly Efficient and Compl...

The PPH spiral wound spray tower is a common wet-type waste gas treatment equipment. Its core operating principle is as follows:

I. Working Process

1. Waste Gas Intake: Acidic (alkaline) waste gas is introduced into the tower base via a fan through an air duct.

2. Gas-Liquid Countercurrent Contact: The waste gas flows upward through the packing layer, where it comes into contact with the absorbent (such as alkali or acid) sprayed from the top of the tower.

3. Absorption and Neutralization: Harmful components in the waste gas (such as HCl, NH₃, SO₂, etc.) undergo physical absorption or chemical reactions with the absorbent, removing them or converting them into harmless substances.

4. Demisting and Dehydration: The purified gas passes through a demisting layer (such as a wire mesh demister or baffle) at the top of the tower to remove moisture before being discharged into the atmosphere by a fan.

5. Liquid Circulation: The absorbent collects in a circulating liquid pool at the bottom of the tower. It is pressurized by a water pump and then sprayed again from the top of the tower, circulating for use until the active ingredients are depleted and replaced.

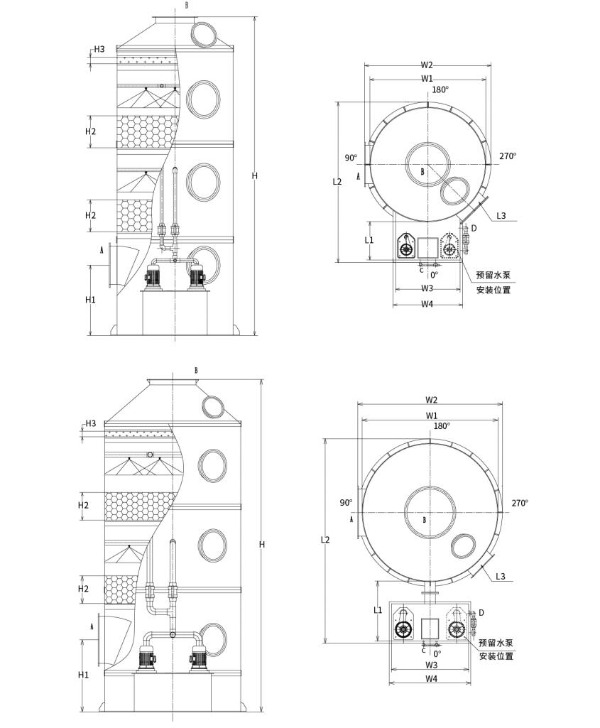

II. Structural Components

- Tower Body: Made of PPH (modified polypropylene) material, this one-piece, weld-free, corrosion-resistant tower is suitable for acidic and alkaline environments.

- Packing Layer: PP ball rings and Raschig rings are commonly used to increase surface area, extend gas-liquid contact time, and improve purification efficiency.

- Spraying System: Consisting of nozzles, pipes, and a water pump, the nozzles evenly spray the absorbent liquid, forming a liquid film covering the packing surface.

- Demisting Layer: Prevents water carryover and ensures dry outlet gas.

III. Technical Features

- High Purification Efficiency: Over 95% can be achieved.

- Corrosion Resistance and Lightweight: PPH material is acid- and alkali-resistant, age-resistant, and suitable for harsh operating conditions.

- Low Operating Resistance: Windage is generally between 200 and 600 Pa, resulting in excellent energy savings.

- Easy Maintenance: Simple structure, easy operation, and a compact footprint.

IV. Scope of Application: Suitable for purifying various acidic and alkaline waste gases such as sulfuric acid mist, hydrogen chloride, and ammonia in industries such as chemical, electroplating, laboratory, and metallurgy.

Chemical Scrubber Selection

Technical Specifications Table for Packed Spray Scrubbers

For transportation convenience and safety, PP-packed spray scrubbers are categorized into two types:

Type 1: Integrated Tank Packed Spray Scrubber (Tower Diameter: Φ1000mm–Φ2200mm)

Type 2: Split-type water tank packed spray scrubber (Tower diameter: Φ2500mm–Φ3500mm)

Airflow Capacity Corresponding Models for Packed Towers:

| Model | Airflow Capacity (m³/h) | Equipment Dimensions | Pump Power | Packing thickness | Wind speed | Equipment Material |

| LRTL-600 | 0 - 1500m³/h | Φ600×3000 | 0.75kw | 500*2 | 1.48m/s | PP/304/Q235/FRP |

| LRTL-800 | 1501 - 2500m³/h | Φ800×3000 | 0.75kw | 500*2 | 1.39m/s | PP/304/Q235/FRP |

| LRTL-1000 | 2501 - 4000m³/h | Φ1000×5000 | 1.5kw | 500*2 | 1.42m/s | PP/304/Q235/FRP |

| LRTL-1200 | 4001 - 6000m³/h | Φ1200×5000 | 2.2kw | 500*2 | 1.48m/s | PP/304/Q235/FRP |

| LRTL-1500 | 6001 - 9500m³/h | Φ1500×5000 | 3.75kw | 500*2 | 1.5m/s | PP/304/Q235/FRP |

| LRTL-1800 | 9501 - 14000m³/h | Φ1800×5000 | 5.5kw | 500*2 | 1.53m/s | PP/304/Q235/FRP |

| LRTL-2000 | 14001 - 17000m³/h | Φ2000×6000 | 5.5kw | 500*2 | 1.5m/s | PP/304/Q235/FRP |

| LRTL-2200 | 17001 - 20000m³/h | Φ2200×6000 | 7.5kw | 500*2 | 1.46m/s | PP/304/Q235/FRP |

| LRTL-2500 | 20001 - 27000m³/h | Φ2500×6000 | 7.5kw | 500*2 | 1.53m/s | PP/304/Q235/FRP |

| LRTL-2800 | 27001 - 33000m³/h | Φ2800×6000 | 15kw | 500*2 | 1.49m/s | PP/304/Q235/FRP |

| LRTL-3000 | 33001 - 38000m³/h | Φ3000×6800 | 15kw | 500*2 | 1.49m/s | PP/304/Q235/FRP |

| LRTL-3200 | 38001 - 44000m³/h | Φ3200×6800 | 15kw | 500*2 | 1.52m/s | PP/304/Q235/FRP |

| LRTL-3500 | 44001 - 55000m³/h | Φ3500×6800 | 15kw | 500*2 | 1.5m/s | PP/304/Q235/FRP |

Note: Custom designs can be provided upon customer request.

Selection Diagram:

|

Service unit customers

National Engineering Cases

Hangzhou Lvran Environmental Protection Group Co., Ltd. is a comprehensive waste gas treatment system engineering service provider and equipment manufacturer, integrating R&D, technical services, design, production, engineering installation, and after-sales service.

We are China PPH winding spray tower Suppliers and Wholesale PPH winding spray tower Exporter, Company. The Group is a national high-tech enterprise, a Zhejiang Province science and technology enterprise, a regional R&D center, and an AAA-rated credit unit. It holds over 30 utility model patents, numerous invention patents, and software copyrights. The Group has long-standing technical R&D collaborations with domestic universities and institutions, including the "Environmental Innovation R&D Center" established with Anhui University of Science and Technology and the "Plasma Energy and Environmental New Technology R&D Center" jointly developed with Zhejiang Sci-Tech University. The Group has established its own R&D and production base for in-depth technical collaboration. The Group possesses core VOC gas treatment technology, holds a Level 2 general contracting qualification for municipal public works construction, a safety production license, a Class B special design qualification for environmental pollution control in Zhejiang Province, unclassified labor service qualifications, and specialized contracting for special projects. The Group is certified to ISO9001 for international quality, ISO14001 for environmental management, and ISO45001 for occupational health and safety.

02 Feb,2026

02 Feb,2026

22 Jan,2026

22 Jan,2026

15 Jan,2026

15 Jan,2026

08 Jan,2026

08 Jan,2026

01 Jan,2026

01 Jan,2026