02 Feb,2026

02 Feb,2026

Is Your Dust Collector System Truly Efficient and Compl...

316L Stainless Steel Spray Tower Operating Principle and Applicable Gas Environment

I. Operating Principle (Same as PP/PPH Tower Process, but Different Materials and Operating Conditions)

1. Exhaust gas enters the tower tangentially, rising through the equalizing section to the packing/spray section;

2. 316L nozzles at the top of the tower atomize NaOH, H₂SO₄, or other chemical solutions into droplets, which come into countercurrent contact with the gas;

3. A liquid film forms on the surface of the 316L Pall ring or stepped ring packing, removing pollutants through absorption, dissolution, neutralization, or redox reactions;

4. The purified gas containing droplets continues through a 316L wire mesh or baffle demister, where it is dehydrated and discharged to standard conditions;

5. Waste liquid is collected in a 316L circulation tank at the bottom of the tower. After automatic dosing and filtration, it is recycled by a 316L pump until it meets discharge standards or is outsourced for treatment.

2. 316L Material Advantages

• Contains 23% Mo, offering over 30% higher resistance to Cl⁻ pitting and crevice corrosion than 304;

• Can withstand long-term use in high-temperature exhaust gases at 80-150°C without deformation or aging;

• High mechanical strength, capable of withstanding pressure fluctuations exceeding ±5 kPa, making it suitable for high-pressure induced draft systems.

III. Typical Applicable Gas Environments

| Industry | Gas Media Examples | Features |

| Chemical/Pharmaceutical | HCl, Cl₂, SO₂, HF, H₂S | High concentration, highly corrosive, halogen-containing |

| Electroplating/Pickling | Chromic acid mist, hydrogen cyanide, nitric acid mist | Contains heavy metal ions, highly oxidizing |

| Waste Incineration | HCl+SO₂+HF gas mixture, dioxin precursors | High temperature, high humidity, complex composition |

| Metallurgy/Electronics | NOₓ, ammonia, silane, phosphine | Fluorine-containing and silicon-containing dusts and strong acids and alkalis |

| Laboratory | Acid-base mixed exhaust gas, organic solvent vapor | Large concentration fluctuations, intermittent emissions |

IV. Comparison with PP/PPH Tower Selection

• Temperature > 60°C or containing fluorine or high chloride ions → Select 316L;

• Containing hydrofluoric acid or high-temperature concentrated sulfuric acid → Upgrade to 904L or Hastelloy;

• For room-temperature weak acid and alkali or cost-sensitive projects, choose PP/PPH.

The 316L stainless steel spray tower utilizes a countercurrent spray-packing mass transfer mechanism, maintaining a purification efficiency of ≥95% and a service life of over ten years even in high-temperature, high-chloride, highly oxidizing, or highly reducing waste gas scenarios. It is the preferred choice for treating corrosive waste gas in industries such as chemical, electroplating, and waste incineration.

Chemical Scrubber Selection

Technical Specifications Table for Packed Spray Scrubbers

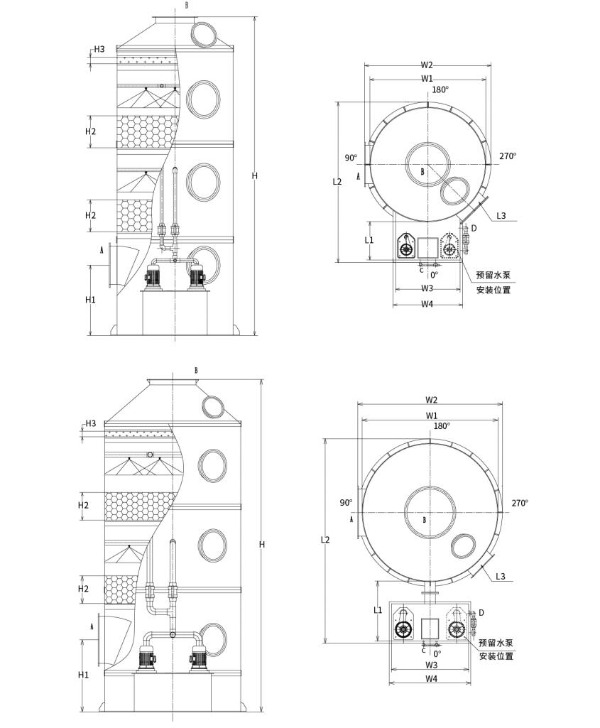

For transportation convenience and safety, PP-packed spray scrubbers are categorized into two types:

Type 1: Integrated Tank Packed Spray Scrubber (Tower Diameter: Φ1000mm–Φ2200mm)

Type 2: Split-type water tank packed spray scrubber (Tower diameter: Φ2500mm–Φ3500mm)

Airflow Capacity Corresponding Models for Packed Towers:

| Model | Airflow Capacity (m³/h) | Equipment Dimensions | Pump Power | Packing thickness | Wind speed | Equipment Material |

| LRTL-600 | 0 - 1500m³/h | Φ600×3000 | 0.75kw | 500*2 | 1.48m/s | PP/304/Q235/FRP |

| LRTL-800 | 1501 - 2500m³/h | Φ800×3000 | 0.75kw | 500*2 | 1.39m/s | PP/304/Q235/FRP |

| LRTL-1000 | 2501 - 4000m³/h | Φ1000×5000 | 1.5kw | 500*2 | 1.42m/s | PP/304/Q235/FRP |

| LRTL-1200 | 4001 - 6000m³/h | Φ1200×5000 | 2.2kw | 500*2 | 1.48m/s | PP/304/Q235/FRP |

| LRTL-1500 | 6001 - 9500m³/h | Φ1500×5000 | 3.75kw | 500*2 | 1.5m/s | PP/304/Q235/FRP |

| LRTL-1800 | 9501 - 14000m³/h | Φ1800×5000 | 5.5kw | 500*2 | 1.53m/s | PP/304/Q235/FRP |

| LRTL-2000 | 14001 - 17000m³/h | Φ2000×6000 | 5.5kw | 500*2 | 1.5m/s | PP/304/Q235/FRP |

| LRTL-2200 | 17001 - 20000m³/h | Φ2200×6000 | 7.5kw | 500*2 | 1.46m/s | PP/304/Q235/FRP |

| LRTL-2500 | 20001 - 27000m³/h | Φ2500×6000 | 7.5kw | 500*2 | 1.53m/s | PP/304/Q235/FRP |

| LRTL-2800 | 27001 - 33000m³/h | Φ2800×6000 | 15kw | 500*2 | 1.49m/s | PP/304/Q235/FRP |

| LRTL-3000 | 33001 - 38000m³/h | Φ3000×6800 | 15kw | 500*2 | 1.49m/s | PP/304/Q235/FRP |

| LRTL-3200 | 38001 - 44000m³/h | Φ3200×6800 | 15kw | 500*2 | 1.52m/s | PP/304/Q235/FRP |

| LRTL-3500 | 44001 - 55000m³/h | Φ3500×6800 | 15kw | 500*2 | 1.5m/s | PP/304/Q235/FRP |

Note: Custom designs can be provided upon customer request.

Selection Diagram:

|

Service unit customers

National Engineering Cases

Hangzhou Lvran Environmental Protection Group Co., Ltd. is a comprehensive waste gas treatment system engineering service provider and equipment manufacturer, integrating R&D, technical services, design, production, engineering installation, and after-sales service.

We are China 316L stainless steel spray tower Suppliers and Wholesale 316L stainless steel spray tower Exporter, Company. The Group is a national high-tech enterprise, a Zhejiang Province science and technology enterprise, a regional R&D center, and an AAA-rated credit unit. It holds over 30 utility model patents, numerous invention patents, and software copyrights. The Group has long-standing technical R&D collaborations with domestic universities and institutions, including the "Environmental Innovation R&D Center" established with Anhui University of Science and Technology and the "Plasma Energy and Environmental New Technology R&D Center" jointly developed with Zhejiang Sci-Tech University. The Group has established its own R&D and production base for in-depth technical collaboration. The Group possesses core VOC gas treatment technology, holds a Level 2 general contracting qualification for municipal public works construction, a safety production license, a Class B special design qualification for environmental pollution control in Zhejiang Province, unclassified labor service qualifications, and specialized contracting for special projects. The Group is certified to ISO9001 for international quality, ISO14001 for environmental management, and ISO45001 for occupational health and safety.

02 Feb,2026

02 Feb,2026

22 Jan,2026

22 Jan,2026

15 Jan,2026

15 Jan,2026

08 Jan,2026

08 Jan,2026

01 Jan,2026

01 Jan,2026