02 Feb,2026

02 Feb,2026

Is Your Dust Collector System Truly Efficient and Compl...

The cyclone scrubber tower typically features a cylindrical tower body equipped with spiral baffle plates. During operation, flue gas enters from the bottom of the tower tangentially and flows upward. Guided by the blades of the baffle plates, the gas spirals upward, atomizing the liquid flowing down the plates into fine droplets. This creates a large gas-liquid contact area. The droplets are carried by the gas stream and rotate, generating centrifugal force that enhances gas-liquid interaction. Eventually, the droplets are thrown onto the tower wall, flow downward along the wall to the next baffle plate, and are re-atomized by the gas stream for further contact. As described, the liquid achieves thorough contact with the gas while maintaining effective separation—minimizing mist entrainment. The gas-liquid load capacity of this system is more than double that of conventional baffle plates.

The tower's excellent gas-liquid contact conditions ensure efficient absorption of waste gases by alkaline liquids. Additionally, the cyclone scrubber tower demonstrates superior dust removal performance. Dust particles in the gas are captured by water mist on the spiral baffle plates, and particles and droplets thrown onto the tower wall by centrifugal force are also effectively removed. As a result, the gas exiting the tower carries minimal dust and droplets. The empty tower wind speed ranges between 2.2–2.7 m/s.

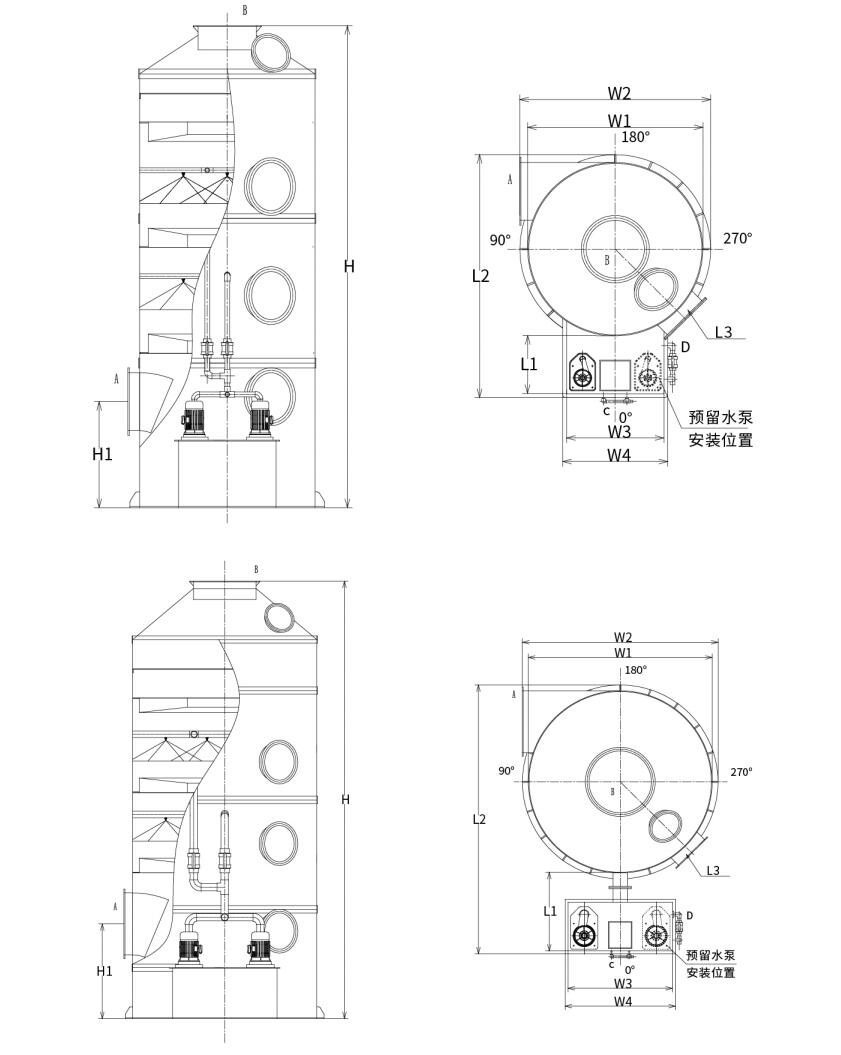

Swirl spray tower structure:

As shown in the figure: The complete packed spray scrubbing system includes the following components:

● Tower body made of PP (polypropylene) sheets;

● Frame constructed with PP spiral baffles;

● Spray connecting pipes made of UPVC (unplasticized polyvinyl chloride);

● PP spiral nozzles;

● Corrosion-resistant PP circulation pump;

● Demister layer (mesh/cyclone/baffle type);

● Manual and automatic water replenishment devices;

● Overflow and drainage pipes;

● Inspection window.

Cyclone plate tower selection parameters:

To ensure transportation convenience and safety, PP cyclone scrubber towers are divided into two specification categories:

Type 1: Integrated water tank cyclone scrubber (Tower diameter: Φ1000mm-Φ2200mm)

Type 2: Split-type water tank cyclone scrubber (Tower diameter: Φ2500mm-Φ3500mm)

Cyclone scrubber tower models corresponding to air flow capacity:

| Model | Air volume range | Device size | Water pump power | Number of swirl blades | Wind speed range | Equipment material |

| XL-600 | 0-2800m³/h | Φ600×2950 | 0.75kw | 2 | 0-2.76m/s | PP/304/Q235/FRP |

| XL-800 | 3800-5000m³/h | Φ800×3300 | 0.75kw | 2 | 2.11-2.77m/s | PP/304/Q235/FRP |

| XL-1000 | 6000-7500m³/h | Φ1000×4380 | 1.5kw | 2 | 2.13-2.66m/s | PP/304/Q235/FRP |

| XL-1200 | 8500-11000m³/h | Φ1200×4430 | 2.2kw | 2 | 2.09-2.71m/s | PP/304/Q235/FRP |

| XL-1500 | 14000-17000m³/h | Φ1500×5000 | 3.75kw | 2 | 2.2-2.68m/s | PP/304/Q235/FRP |

| XL-1800 | 20000-25000m³/h | Φ1800×5650 | 5.5kw | 2 | 2.19-2.73m/s | PP/304/Q235/FRP |

| XL-2000 | 25001-30000m³/h | Φ2000×6200 | 5.5kw | 2 | 2.21-2.66m/s | PP/304/Q235/FRP |

| XL-2200 | 30001-37000m³/h | Φ2200×6700 | 7.5kw | 2 | 2.19-2.71m/s | PP/304/Q235/FRP |

| XL-2500 | 40000-47000m³/h | Φ2500×6850 | 7.5kw | 2 | 2.27-2.66m/s | PP/304/Q235/FRP |

| XL-2800 | 49000-58000m³/h | Φ2800×7900 | 11kw | 2 | 2.21-2.62m/s | PP/304/Q235/FRP |

| XL-3000 | 58000-68000m³/h | Φ3000×8000 | 11kw | 2 | 2.28-2.67m/s | PP/304/Q235/FRP |

| XL-3200 | 68000-78000m³/h | Φ3200×8000 | 15kw | 2 | 2.35-2.7m/s | PP/304/Q235/FRP |

| XL-3500 | 78000-88000m³/h | Φ3500×8000 | 15kw | 2 | 2.25-2.54m/s | PP/304/Q235/FRP |

Note: Non-standard designs can be made according to customer requirements.

Selection diagram:

Service unit customers

National Engineering Cases

Hangzhou Lvran Environmental Protection Group Co., Ltd. is a comprehensive waste gas treatment system engineering service provider and equipment manufacturer, integrating R&D, technical services, design, production, engineering installation, and after-sales service.

We are China Cyclone Plate Wet Scrubber Suppliers and Wholesale Cyclone Plate Wet Scrubber Exporter, Company. The Group is a national high-tech enterprise, a Zhejiang Province science and technology enterprise, a regional R&D center, and an AAA-rated credit unit. It holds over 30 utility model patents, numerous invention patents, and software copyrights. The Group has long-standing technical R&D collaborations with domestic universities and institutions, including the "Environmental Innovation R&D Center" established with Anhui University of Science and Technology and the "Plasma Energy and Environmental New Technology R&D Center" jointly developed with Zhejiang Sci-Tech University. The Group has established its own R&D and production base for in-depth technical collaboration. The Group possesses core VOC gas treatment technology, holds a Level 2 general contracting qualification for municipal public works construction, a safety production license, a Class B special design qualification for environmental pollution control in Zhejiang Province, unclassified labor service qualifications, and specialized contracting for special projects. The Group is certified to ISO9001 for international quality, ISO14001 for environmental management, and ISO45001 for occupational health and safety.

02 Feb,2026

02 Feb,2026

22 Jan,2026

22 Jan,2026

15 Jan,2026

15 Jan,2026

08 Jan,2026

08 Jan,2026

01 Jan,2026

01 Jan,2026